Busbar Bending Machine: Revolutionizing Electrical Panel Manufacturing

AlexJones

- 0

- 612

In the ever-evolving world of electrical engineering, innovation is the key to efficiency and productivity. One remarkable innovation that has been making waves in the industry is the busbar bending machine. This ingenious piece of equipment has brought about a significant transformation in the way electrical panels are manufactured and assembled.

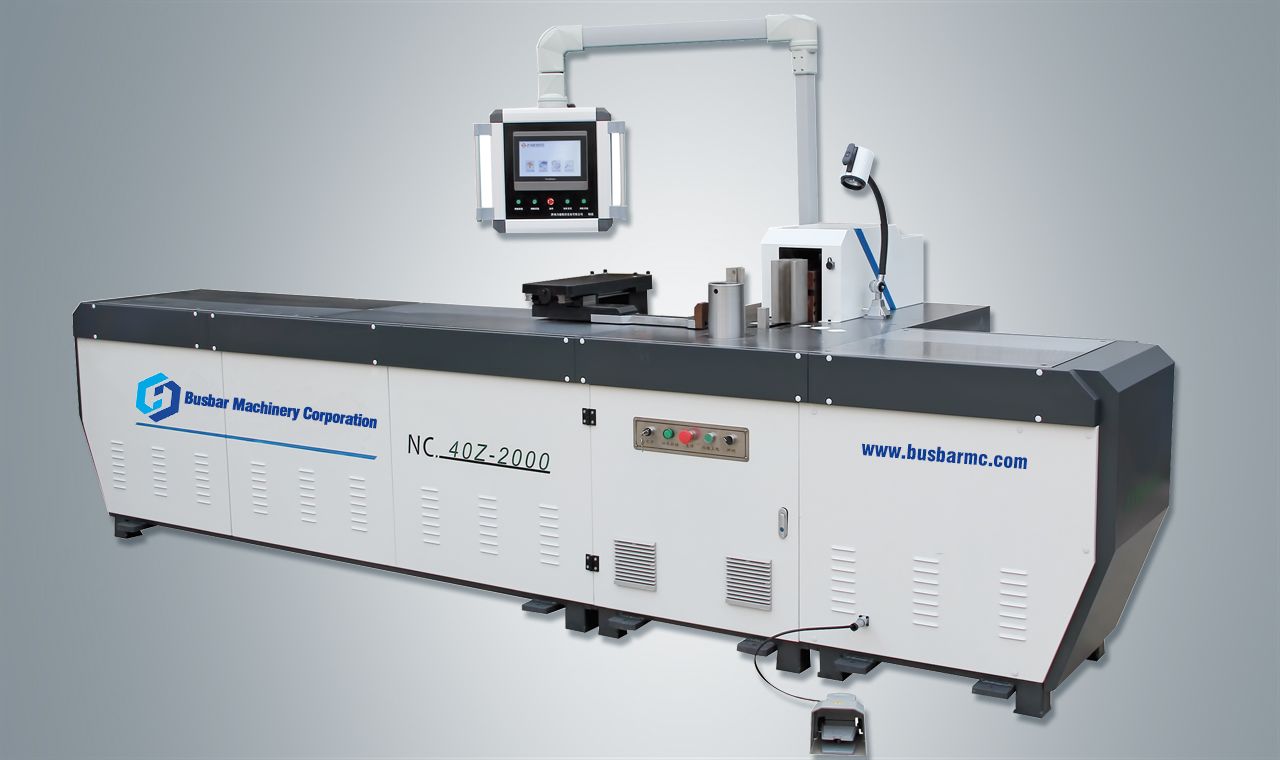

Traditionally, the process of bending and shaping busbars, the critical components in electrical panels, was a labor-intensive and time-consuming task. Skilled technicians spent hours meticulously bending copper or aluminum bars by hand, a process that was not only slow but also prone to human error. The Busbar Bending Machine has changed the game by automating this crucial step. With precision and speed, it bends busbars into the required shapes, reducing production time and ensuring accuracy.

Accuracy is paramount in electrical panel manufacturing. A slight deviation in the shape or dimensions of a busbar can lead to electrical issues, downtime, and costly repairs. Busbar Bending Machines employ advanced technology to guarantee precision. They can bend busbars to exact angles and lengths, meeting the stringent requirements of modern electrical systems.

Electrical panels come in various shapes and sizes to accommodate the specific needs of different industries and applications. Busbar Bending Machines offer a high degree of flexibility in design. Whether it’s a straight bend, Z-bend, or even complex multi-bend configurations, these machines can handle it all. This versatility allows electrical engineers to create customized panels that fit perfectly into their projects.